Underwater construction is a unique and complex field of engineering that involves building, repairing, and maintaining structures beneath the water’s surface. Whether it’s constructing offshore oil rigs, laying submarine cables, building bridges over rivers, or creating underwater tunnels, each project presents distinct challenges that require specialized skills, equipment, and meticulous planning.

In this article, we will walk through the key phases of an underwater construction project—from the initial concept all the way to completion—and explore the essential elements that make these projects successful.

1. Conceptualization: Laying the Foundation

The first step in any underwater construction project is conceptualization. This phase involves defining the project’s goals, understanding the environmental and logistical challenges, and assessing the feasibility of construction in an underwater environment.

Project Planning and Design

During the conceptualization phase, engineers and architects work closely with marine biologists, environmental consultants, and other specialists to design the project. The aim is to ensure that the construction plan will meet all regulatory requirements, environmental standards, and safety protocols while also fulfilling the project’s objectives.

Key elements during conceptualization include:

- Site Survey and Environmental Impact Assessment: Engineers will assess the underwater site to understand the seabed conditions, water currents, and environmental considerations. Marine life and potential disruptions to the ecosystem must be taken into account.

- Designing for Conditions: The design of the structure (whether it’s a pier, a tunnel, or an offshore platform) will be adjusted to account for underwater pressure, temperature, tides, and the type of material that will be used.

Permitting and Regulatory Approval

Given the sensitive nature of underwater construction, regulatory agencies must approve the project before any physical work begins. This includes obtaining permits for construction, navigation, and environmental protection. Permitting requirements vary based on location, scope, and type of construction being undertaken.

2. Preparation: Gathering Resources and Mobilization

Once the design has been finalized and permits are in place, the project transitions to the preparation phase. This stage involves gathering all the necessary resources, including personnel, equipment, materials, and technology.

Mobilizing Equipment

Underwater construction often requires specialized equipment and machinery, including:

- Divers: Skilled divers equipped with scuba gear or surface-supplied diving systems.

- Remotely Operated Vehicles (ROVs): These are often used for inspection, data collection, and handling tasks in deep waters or hazardous conditions.

- Cranes and Heavy Machinery: These may be used for transporting and positioning large construction materials and structures.

- Submersible Construction Platforms: Floating platforms equipped with tools and materials for underwater construction.

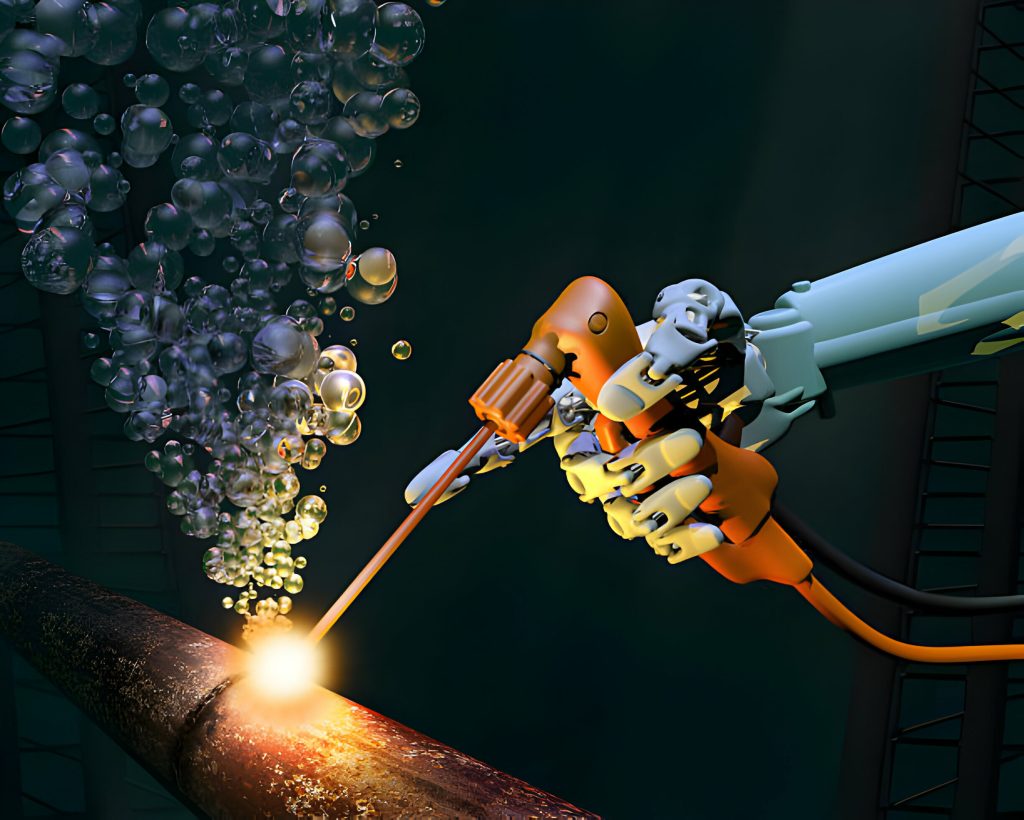

- Robotic Arms: For precision tasks like welding, cutting, or assembly at depth.

Staffing

Skilled workers, including marine engineers, divers, underwater welders, project managers, safety experts, and environmental specialists, must be brought on board. Many of these workers undergo intensive training to work safely in underwater environments.

3. Construction: Building Below the Surface

Once all preparations are complete, the actual construction begins. This phase involves a combination of human labor and advanced machinery, often working in harmony to overcome the challenges presented by working underwater.

Construction Techniques

Several underwater construction techniques are employed, depending on the type of structure being built:

- Diving and Manual Work: Some tasks, such as underwater welding, pipe installation, or concrete pouring, require human divers. These workers are typically equipped with specialized tools, communication devices, and life-support systems.

- Pre-cast or Modular Construction: In many underwater projects, especially those involving large offshore platforms or bridges, pre-cast or modular construction is used. These modules are built on land and then submerged and assembled in place. This method reduces the complexity of on-site work and the risk of adverse environmental effects.

- Underwater Welding and Cutting: Underwater welding is a key technique used for building and repairing structures. It requires specialized equipment and safety measures, as the process involves working in high-pressure, low-visibility environments.

- Grouting and Concrete Pouring: In underwater construction, cement and grout are often pumped into the seabed or surrounding areas to form foundations or secure structures.

Tools and Technology

Modern underwater construction relies on sophisticated tools, including sonar imaging, laser scanning, and 3D modeling. These technologies help create detailed maps of the ocean floor and provide real-time information to engineers and workers. ROVs and AUVs (Autonomous Underwater Vehicles) may be used for surveillance and inspection, ensuring construction quality and identifying potential issues early.

4. Monitoring and Inspection: Ensuring Quality and Safety

Throughout the construction process, constant monitoring and inspection are crucial to ensure the safety, quality, and environmental impact of the work.

Ongoing Inspection

ROVs are often deployed to monitor the progress of the project. They collect data through high-definition cameras, sonar equipment, and environmental sensors. The information is analyzed to ensure that the construction is proceeding according to plan and that no damage is being caused to the surrounding marine environment.

Environmental Protection

Construction teams must adhere to strict environmental guidelines to prevent pollution, habitat destruction, or damage to marine ecosystems. Efforts are made to minimize the impact on marine life, with techniques such as silt barriers and air-lifting technology used to control sediment and debris.

5. Finalization: Testing, Certification, and Handover

Once construction is complete, the final phase involves testing, certification, and handover to the client or project owner. This ensures that the structure meets all safety, performance, and regulatory standards.

Testing and Quality Assurance

Before a structure can be deemed operational, it undergoes rigorous testing. For underwater construction projects like offshore platforms or pipelines, this may involve pressure tests, structural assessments, and stability checks. The goal is to confirm that the structure can withstand environmental forces and operate safely over the long term.

Environmental Monitoring and Reporting

An environmental monitoring plan is typically set in place during the finalization stage. This ensures that the surrounding ecosystem remains unaffected by the construction process. Post-construction monitoring helps detect any changes in water quality or marine life, allowing for prompt action if needed.

Handover

Once testing is complete and the structure has passed all certifications, it is officially handed over to the client for operation. This might include transferring control of an offshore oil platform to an energy company or opening a newly constructed underwater tunnel for public use.

6. Maintenance and Longevity: Ensuring the Structure’s Lifespan

After the project is completed and in operation, underwater structures require continuous maintenance to ensure their longevity. Marine environments are harsh, with corrosion, biofouling, and other natural forces taking a toll on the structure over time. Routine inspections, repairs, and upgrades are crucial to keep the structure functional and safe.

Maintenance Techniques

- Robotic Inspection: Regular checks by ROVs are used to inspect hard-to-reach areas or assess damage caused by marine life or natural forces.

- Underwater Welding and Repair: If any damage is found, underwater welding or other repair methods can be applied to restore the integrity of the structure.

Conclusion

From concept to completion, underwater construction projects involve complex planning, cutting-edge technology, and a highly skilled workforce. Every step—from initial design and environmental assessments to the actual construction and ongoing maintenance—requires careful attention to detail and precision.

Through innovation and expertise, engineers are pushing the boundaries of what’s possible below the surface, creating vital infrastructure that supports industries ranging from energy to transportation. As technology continues to evolve, the future of underwater construction promises even greater capabilities and efficiencies, enabling the creation of sustainable, resilient structures that will stand the test of time beneath the waves.